Low dew point dehumidification modular units

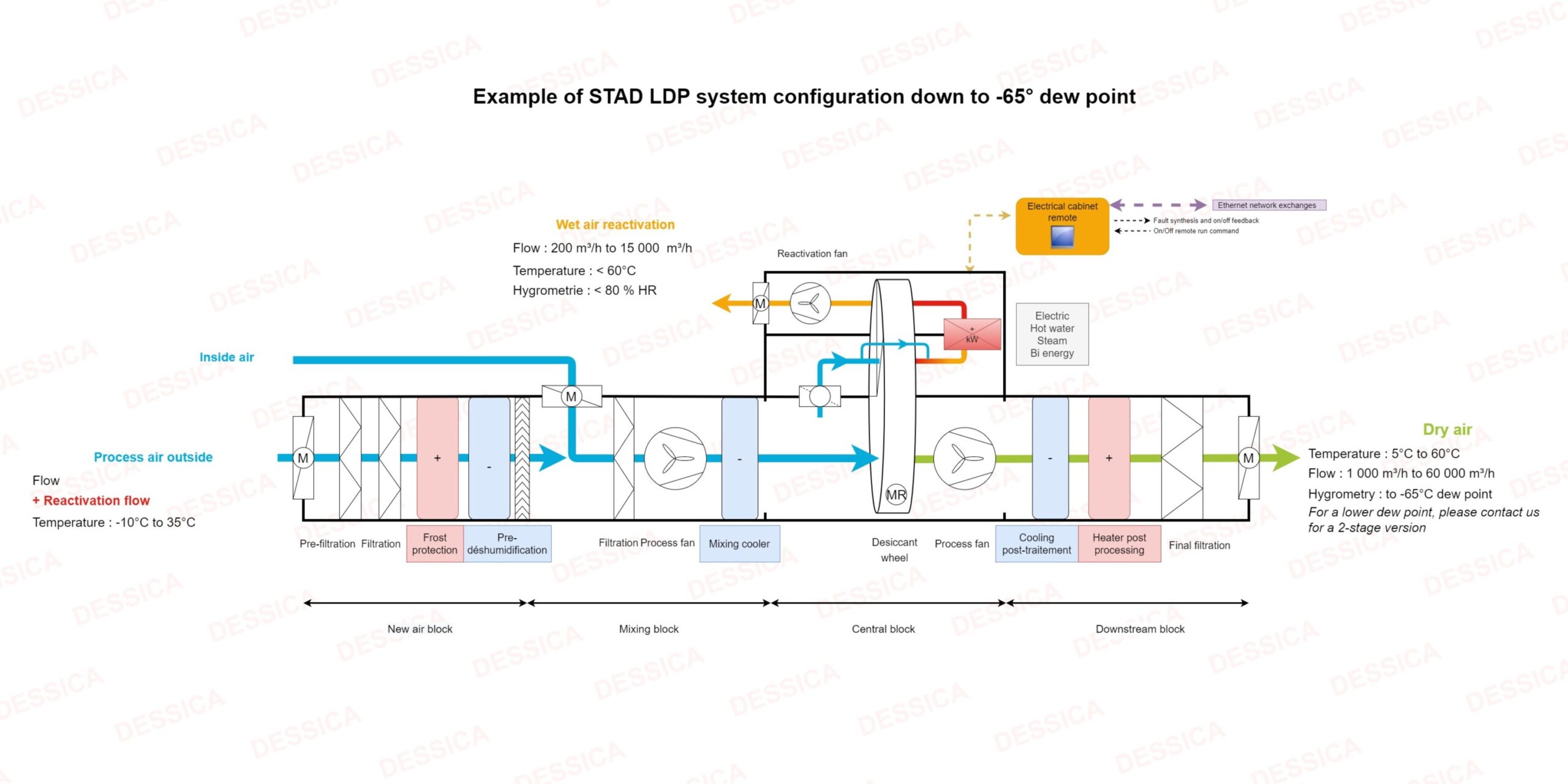

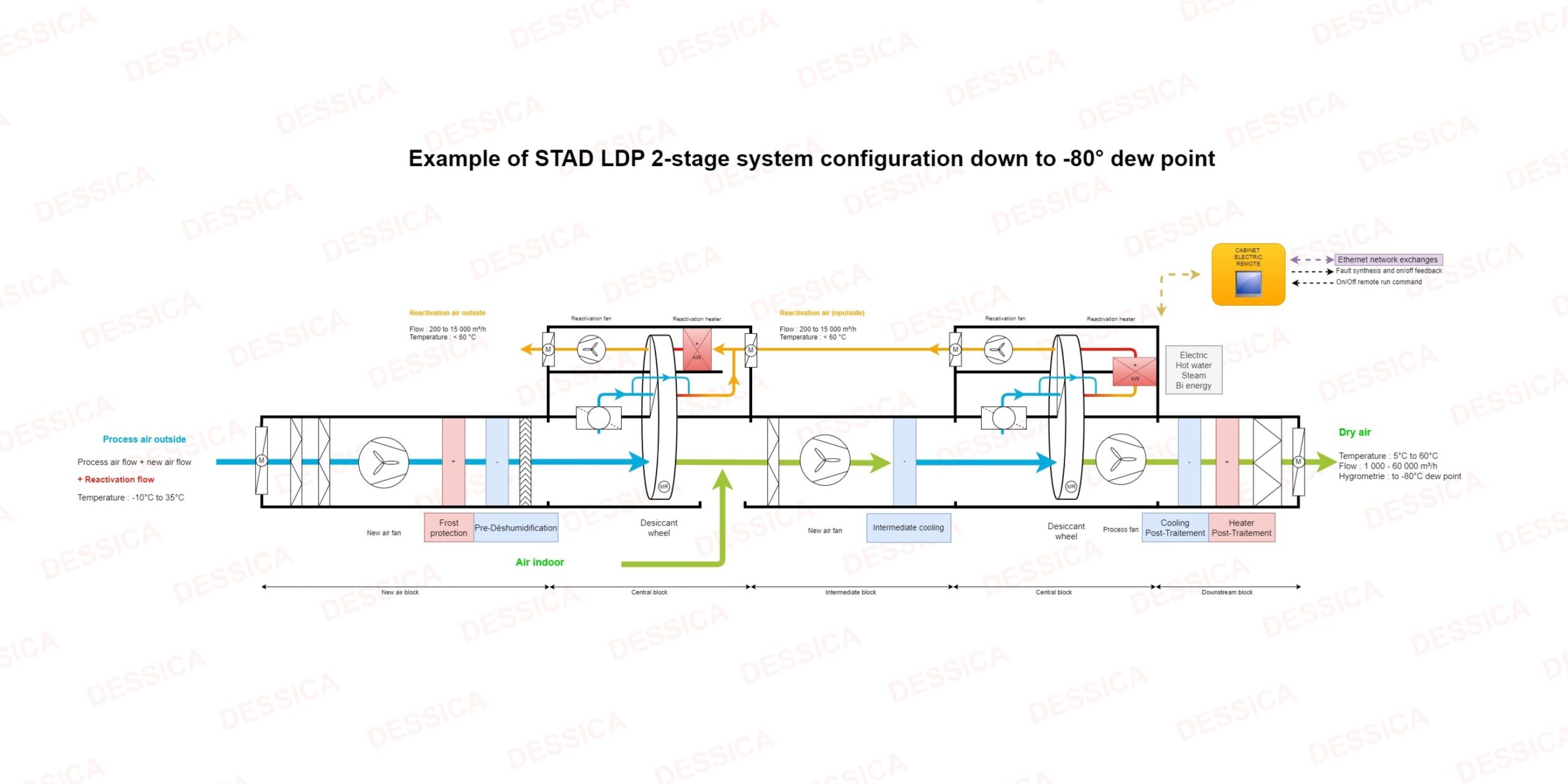

STAD dehydration systems are designed to provide accurate dry air quality. These systems offer a complete solution with filtration, heat exchangers, adapted control system… The unit is fully configurable according to your needs and application.

Description of Low dew point dehumidification modular units

STAD dehydration systems are designed to provide accurate dry air quality. These systems offer a complete solution with filtration, heat exchangers, adapted control system… The unit is fully configurable according to your needs and application.

The third-generation PPS and PPX silicagel dehydrating wheels that equip our systems have very high levels of active silicone. They ensure a very high dehumidification performance and reduce energy consumption compared to devices equipped with other dehydrating silicone wheels of the same size.

They are built in self-supporting panels for greater rigidity: prepainted sheet on the outside and galvanized steel sheet on the inside.

The system is modular and offers a customized dehydration solution.

Heat recovery solutions can be installed to improve the energy efficiency of systems.

STAD systems produce dry air to supply air treatment processes in anhydrous rooms. DESSICA supplies electric vehicle battery manufacturers. The anhydrous environment is essential for the assembly of the components and to prevent their oxidation in contact with the water contained in the air. In lithium battery laboratories and research centers, the required humidity must be extremely low.

Operation dehumidification modular units

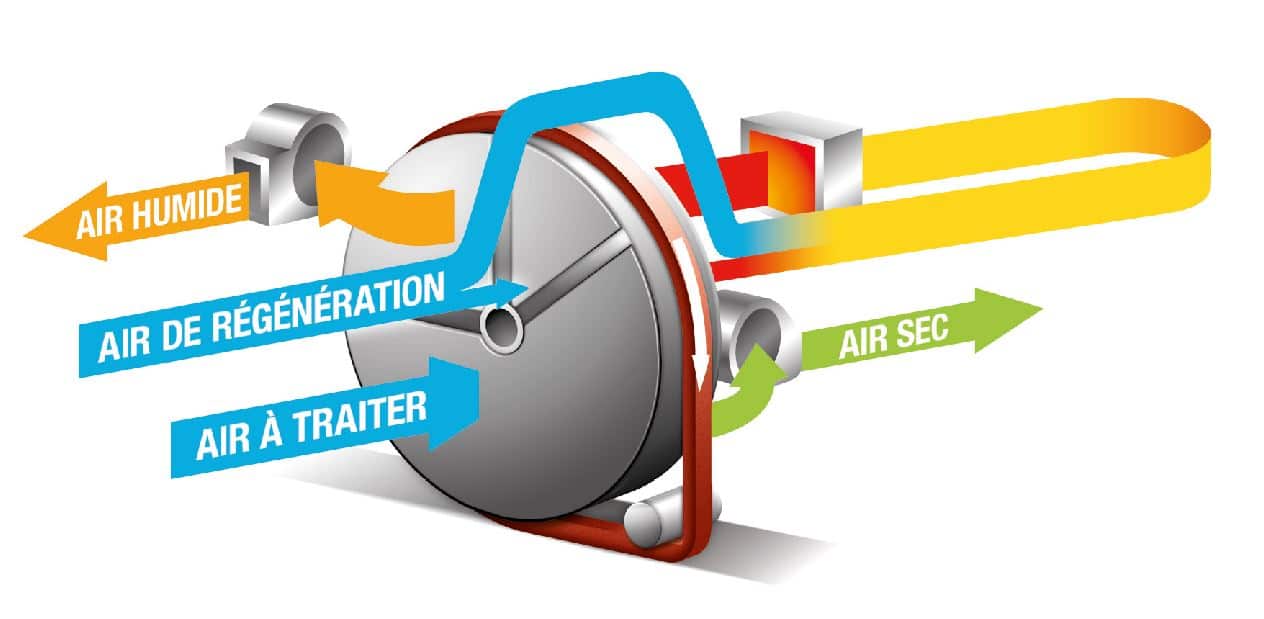

The STAD dehydrator uses two independent air streams.

The main air flow will be dried out, the secondary flow, of lower volume, will be used to remove moisture retained by the dehydrating wheel.

Two fans move two separate, counter-current air streams through the dehydrating wheel.

The main or air stream to be treated crosses the slow-rotating silica wheel. Silicagel is a highly hygroscopic material capable of holding water vapor contained in ambient air. When the wheel is crossed, the air to be treated loses its moisture retained by the silicagel. Dry air is then directly usable.

The secondary air flow, called regenerative air, is used to remove the moisture held by the silicagel from the wheel. The regenerating air is heated to a temperature of about 100°C to 130°C by heating with an electric, steam or direct gas battery, then crosses the counter-current wheel of the air stream to be treated to remove the silicagel from its humidity. Wet regeneration air (humid air) leaves the dehydrator to be evacuated outside the premises or building.

Benefits of very low dew point desiccant air treatment systems

- Specially designed to treat very low dew point

- Very high wapor tightness

- Modular and adaptable

- Double skin insulation 50mm

- PLC automated control

- Very high dehumidification performance

- Reducing energy consumption compared to devices equipped with other silica gel desiccant rotors of the same dimensions

- Heat recovery solutions can be installed to improve the energy efficiency of systems

Applications for modular dehumidification and air treatment for low dew point

STAD systems produce dry air to supply anhydrous room air treatment processes.

DESSICA supplies electric car battery manufacturers. The anhydrous environment is essential for the assembly of the components and to prevent their oxidation in contact with the water vapor contained in the air. In lithium battery laboratories, the required humidity must be extremely low.

Applications

Discover our products and solutions in applications