Adjustable rotary adsorption dryers

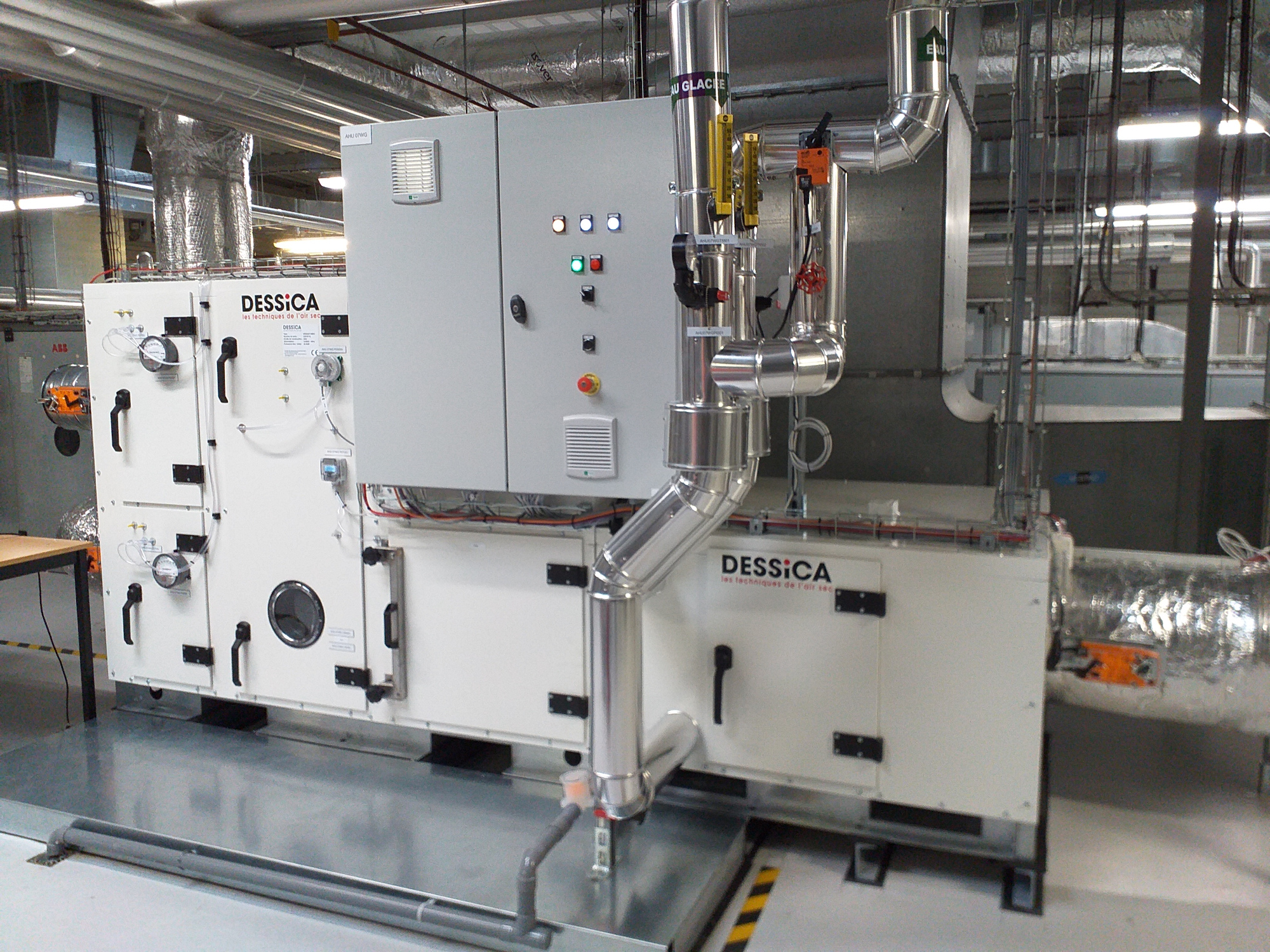

Dessica DS systems are modular dehumidification an air treatment unit (hygrometry, temperature and dust) specially designed to meet the requirements of users for building or industries.

Description

The process of dehumidifying air with solid adsorbents involves use of the properties of an agent with a high affinity for water. Our systems include a desiccant rotor based on silica gel (SiO2) or molecular sieves. These systems can be used down to very low humidity (-60°C dew point).

They have the advantage of being able to use energies other than electricity to dehumidify the air, such as superheated water, steam or gas with a burner directly in the air stream.

The third-generation PPS and PPX silica gel desiccant rotors that equip our air dryers have very high levels of active silica gel, ensuring very high dehumidification performance and reducing energy consumption compared to devices equipped with other silica gel desiccant rotors of the same dimensions.

Adjustable dryers are especially designed to adapt to the various needs of the users in the building or the industry. They include the latest innovations, in particular the integrated heat recovery system. They allow us to offer a complete solution with filtration, hot and cold batteries, control system, etc.

Find the right humidity control system for you, whatever your line of work

Excess humidity and moisture are serious issues that affect a great, many industries. First and foremost, any business that has to handle foodstuffs on a regular basis will probably require some sort of humidity control. Food processing plants, for example, need a dry, sterile environment that will reduce the risk of microbiological contamination to an absolute minimum. The kind of atmosphere delivered by industrial humidity control systems also bring benefits for the workforce in the shape of safer, more hygienic working conditions.

If you’re producing bread and pastries on an industrial scale, a Dessica humidity control system is just what you need to counter a key challenge faced by businesses in this sector – the avoidance of the kind of product stickiness which can be complicated on conveyor belts.

Lastly, dry air is critical to any company that’s involved in seed storage & preservation, principally to ward off germination and to boost seed dormancy.

In addition to the food processing segment, industrial humidity control has a major part to play in the chemical and pharmaceutical industries, with applications at multiple stages in the medication manufacturing process (capsule-filling, powder compression, effervescent pill, the production and storage of items such as lithium-ion batteries (the creation of dry rooms).

Operating principle of the desiccant rotor with an integrted heat recovery

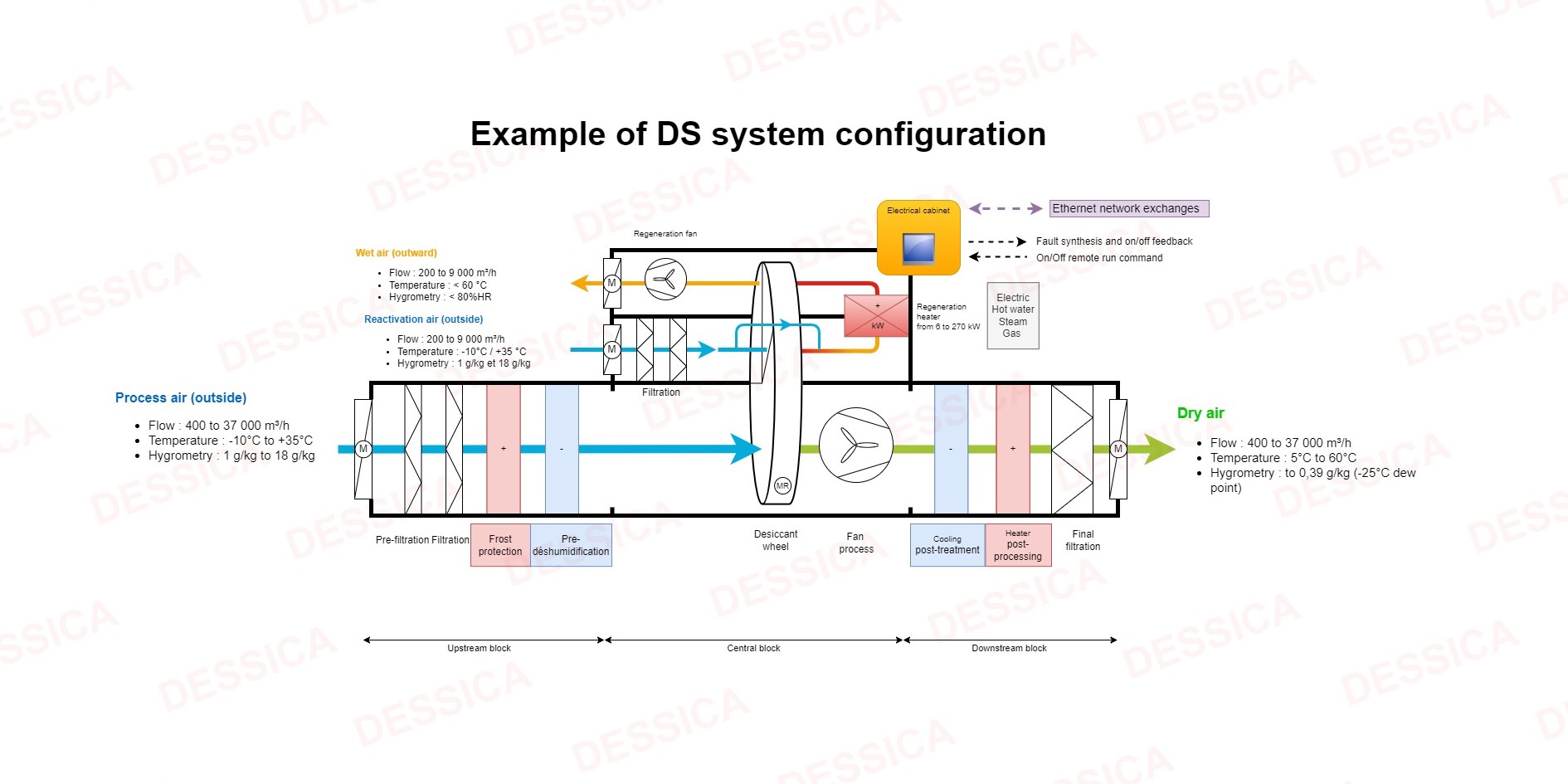

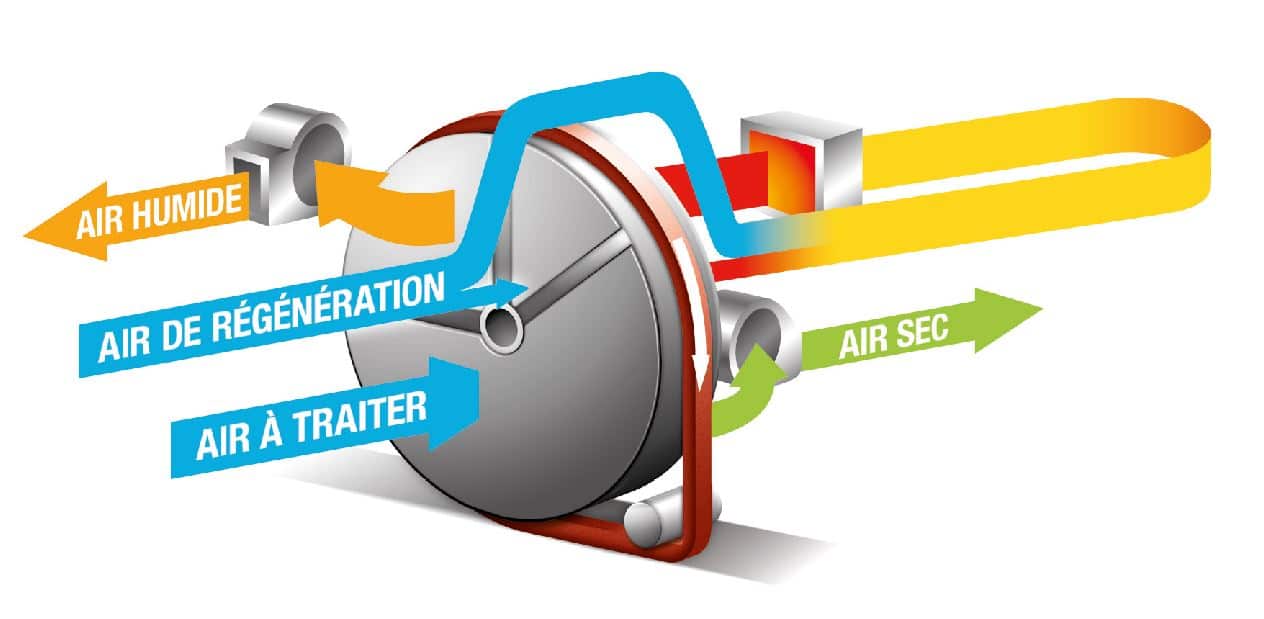

The DS system uses two independent air flows. The main air flow will be dried, the secondary air flow of lesser volume will be used to evacuate the moisture retained by the desiccant rotor.

Two fans move to distinct air steams through the desiccant rotor. Thamin air steam or air to be treated passes through the slowly rotating silicagel rotor. Silicagel is a high-performance hygroscopic material able to retain the moisture content from ambient air. By floating through the rotor, the humid air loses its moisture captured by the silicagel material. The dry air is the totally usable.

The secondary air flow, called reactivation air, serves to evacuate the moisture retained by the rotor silica gel component. A part of the air volume passes through the rotor by the heat recovery sector, cooling down the dehydrating material by simultaneously raising the air temperature. Th remaining flow by-passing the rotor is mixed with purge air flow.

The preheated air is then brought to a final temperature approximately 210 F et 270F (100°C to 130°C) by additional heating provided electric, steam or direct gas coil. It will pass through the rotor by counter current from process air flow to dry off the silicagel from its moisture. The moisten air (wet air) leaves the dryer to be evacuated outside the premises or building.

The benefits of modular units for dehumidification and air treatment

- Complete solution including ffiltration, heat exchangers and adaptated regulation

- Modular and adaptable

- Third generation PSS and PPX silicagel desiccant rotor with high dehumidification performance

- Latest innovation for adsorption desiccant rotors

- Double skin 2 inches

- PLC automated control

- Indoor & outdoor versions

- Integrated Heat Recovery

- Reduce energy consumption compared to other silicagel desiccant of the same dimensions

Application for modular dehumidification and air treatment units

DESSICA DS systems supplies dry air to drying processes, production or again packaging and storage environments. They are designed to treat or be installed in air conditions between 5F and 100 F (-15°C and 40°C).

Mastering hygrometry makes possible to control specific products and systems:

- the production capacity of drying systems (ovens, towers, fluidized beds…)

- clogging and bulking of pulverized products

- corrosion

- condensation

- the quality of hygroscopic materials

- the development of bacteria and the spread of micro-organisms

- icing

- the humidity level in building

- mold

Some industries such as pharmaceutical, food processing, energy, metallurgy and electronics requires a precise and high dry air quality, this is what DESSICA DS system provide.

Dessica Dryair humidity control is set to become even more eco-friendly

Dessica has recently filed a ground-breaking new patent that is hoped will cut down on energy consumption and link up to sources of greener power generation. Centring around rotation of the speed of the desiccant wheel – a key component of industrial humidity control systems – this new patented system can be run off electricity generated by solar panels. As well as burnishing the company’s green credentials, this new technology also represents a boon for any business seeking to reduce the running costs of their dehumidification and humidity control operations.

Applications

Discover our products and solutions in application