Many configurations

Casing in stainless steel

High performance desiccant rotor

Configurable access easement

Simple maintenance

High efficiency fans with EC motor

Integrated controls (humidity, temperature and air flow rates)

Programmable logic controller (PLC)

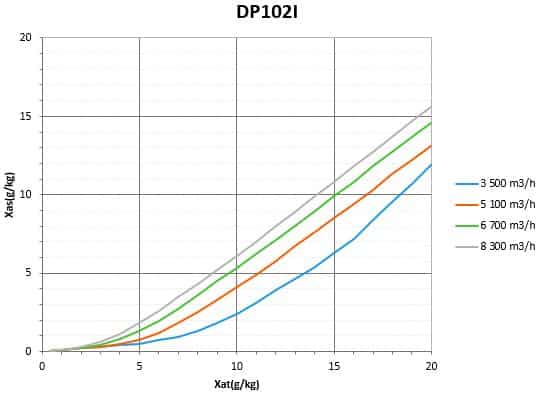

Air dehumidifiers for industrial processes DP102I

Price on request

Learn more about the air dryer DP102I

The DP range of dehumidifiers is designed to meet the different needs of users in industry, particularly for production and packaging environments and drying processes.

DP rotary dehumidifiers operate using the solid adsorbent air dehumidification process. The DP are equipped with a continuously regenerated high performance PPS silica gel desiccant wheel. They also include a double skinned 30mm insulated stainless steel casing, two fans with EC motor (electronic commutation), single or double stage filtration, a regeneration heating coil, a power and control panel controlled by a PLC.

Dry air flow range : de 3500 à 8300 m3/h

Wet air flow : 1575 m3/h

Available pressure : 700 Pa

Electrical power : 47,25 kW

In addition to the adsorption air dehumidification system, the DP units can be configured with the following equipment and functions :

➔ Filtration

- Pre-filtration from G4 to F9

- Final filtration from F8 to H14

➔ Regeneration heater

Electric heater

Air/steam heat exchanger

Air/water heat exchanger

Air stream gas burner

➔ Control

Regeneration temperature

External start and operation return

Rotor rotation guard

Operating time

Filter guard

TCP IP communication with Ethernet or RS485 port

Each DP is equipped with an electrical cabinet containing the power and control elements including:

- Circuit breaker

- Automatic control screen

- Emergency stop button

The PLC manages the following functions:

- Start and stop sequence

- Machine safety

- Faults

The following functions are available on the screen:

- Operating mode

- Faults

- Setpoint and control parameters

➔ Integrated heating or cooling in additional units

Chilled air/water heat exchanger

Air/hot water or water/steam exchanger

Electric heater

➔ PID control

Humidity

Process air flow rate

Regeneration air flow rate

Pre-treatment temperature

Post-treatment temperature