Desiccant air treatment systems

The STAD systems are modular and adaptable.. These systems produce large volumes of dry air. They are specially designed to meet the requirements of users in industry and food processing:

- self-supporting panels (painted or stainless steel 304L or 316L) double skinned (without aluminium sides) insulated by 50mm high-density mineral wool.

- made with food contact material for hygienic version

- easy access with maintenance doors.

Description dehumidification systems

These systems include the latest innovations for adsorption desiccant rotors and use the new energy saving system (Ovir® patent).

These systems also include :

- Energy recovery system : on wet air to preheat reactivation air

- External fan (recommended for hygienic food processing version) or internal fan

- Remote electrical cabinet.

- The third generation and silica gel desiccant rotors mounted on our air dryers contains a high active silica gel component.

It provides a high dehumidification performance and reduce energy consumption compared to other silica gel desiccant rotors of the same dimensions.

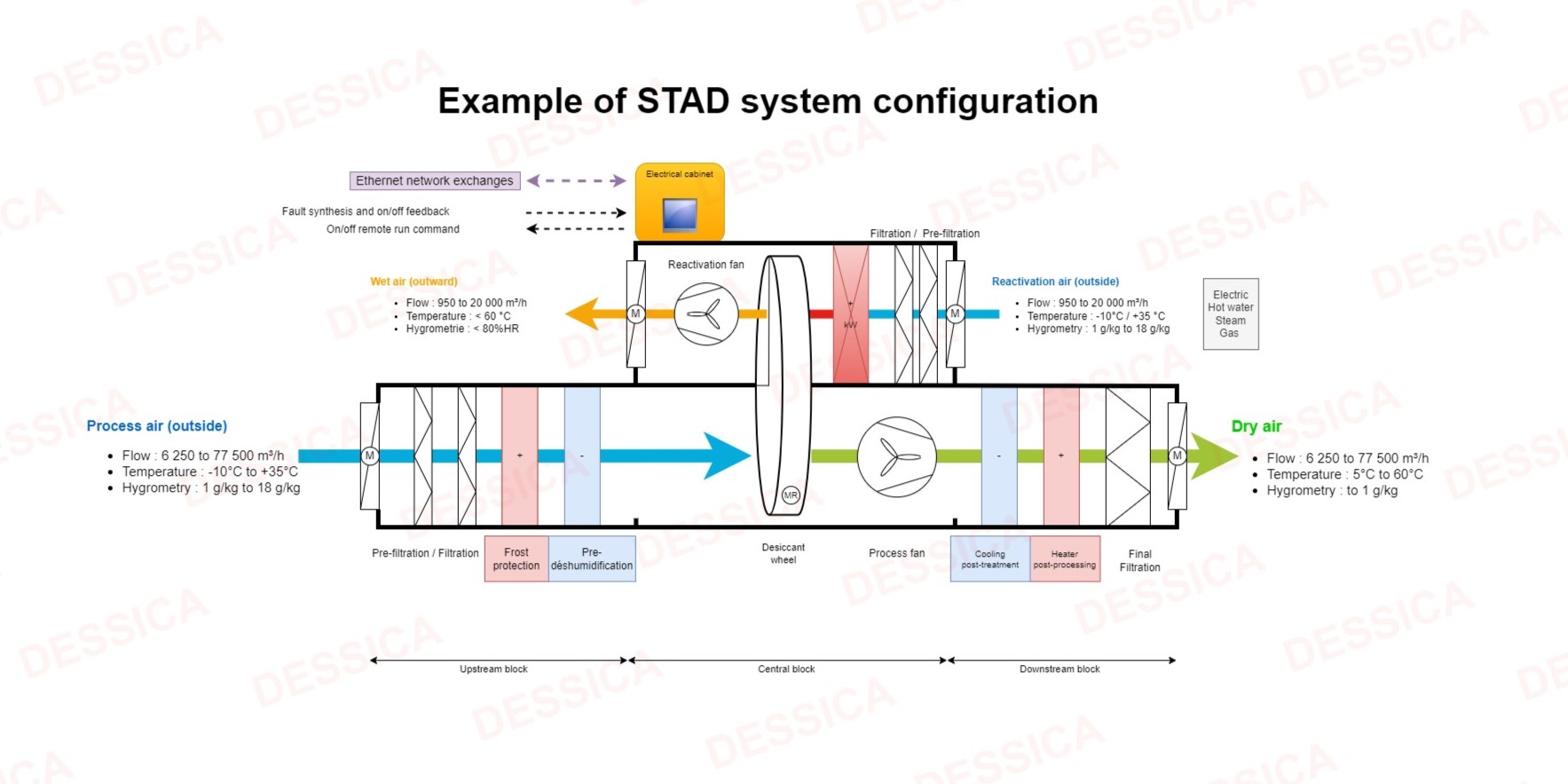

Operation dehumidification modular units

DESSICA systems uses two independent and counter current air flows through the desiccant rotor, with a slow and continuous pace :

- the main air flow (process air) is dried

- the secondary air flow (reactivation air), of lesser volume, is used to evacuate the humidity retained by the desiccant rotor

Two fans set in motion both air streams.

Silica gel is a high- performance hygroscopic material able to retain the moisture content from ambient air. Through the rotor, the humid air loses its moisture captured by the silica gel material. The dry air is then totally usable.

Reactivation air purpose is to evacuate the moisture captured by the silica gel in the rotor. The air is brought to an approximate temperature of 210°F to 320°F (100°C to 160°C) and then crosses the rotor against the wet air flow to remove the moisture retained in the silica gel. The moist reactivation air leaves the dehumidifier to be evacuated outside the building or any other premises.L’air de régénération humide quitte le déshydrateur pour être évacué à l’extérieur des locaux ou du bâtiment.

Benefits of Desiccant air treatment systems

- Modular and adaptable

- 2 Versions painted or stainless steel 304L or 316L

- Hygienic version with food contact materials

- Double skin insulation

- Maintenance doors

- Ovir® patented energy saving system

Applications

Discover our products and solutions in application