Dehumidifying the air to combat corrosion

Corrosion is a natural oxidation process that occurs when metals are exposed to moist air. This process can severely damage metal structures, industrial equipment, and lead to significant costs in maintenance and repairs. However, this phenomenon can be prevented by acting upstream on the air humidity. Corrosion can be stopped before it even begins forming, by keeping the relative humidity below 60%.

Why control humidity to prevent corrosion?

Humidity control is a preventive measure that can slow down or even stop the corrosion process. When relative humidity exceeds 60%, corrosion begins to form, gradually increasing over time. By lowering this level below this threshold, we protect materials, whether industrial equipment, metal structures or sensitive structures.

Sectors concerned with the fight against corrosion

Many industrial sectors face the issue of corrosion, particularly those operating in environments with high humidity levels.

Dehumidification is essential in:

- Nuclear power plants and hydroelectric stations during maintenance phases.

- Water treatment stations where corrosion can damage buildings and equipment.

- The painting and surface treatment sector: surface preparation before the application of coatings must be done in humidity-free conditions.

- The storage of metal parts in the aerospace, maritime, or industrial sectors to prevent corrosion during warehousing periods.

- The offshore wind energy industry and the shipbuilding industry, where particularly corrosive marine environments require strict control of air humidity.

- Civil engineering works: controlling humidity is crucial to extend the lifespan of civil engineering structures such as bridges, viaducts, dams, or tunnels. Dehumidifiers maintain a constant flow of dry air within these structures.

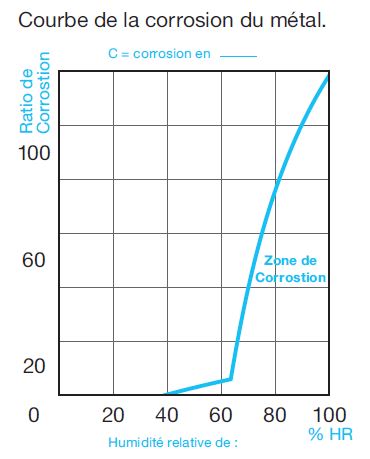

Metal corrosion curve

This diagram illustrates the relationship between the corrosion coefficient of steel and the relative humidity of the air. It shows that this coefficient does not follow a linear variation with humidity. A significant decrease in the coefficient can be observed when relative humidity lowers to 60%. It tends towards zero at 35% R.H. Below this threshold, corrosion becomes impossible.

Corrosion is also influenced by temperature. The higher the temperature is, the more corrosion increases. Below -2°C, its impact becomes negligible. Air pollution also plays a major role, significantly amplifying corrosion phenomena.

Desiccant wheel dehumidification technology

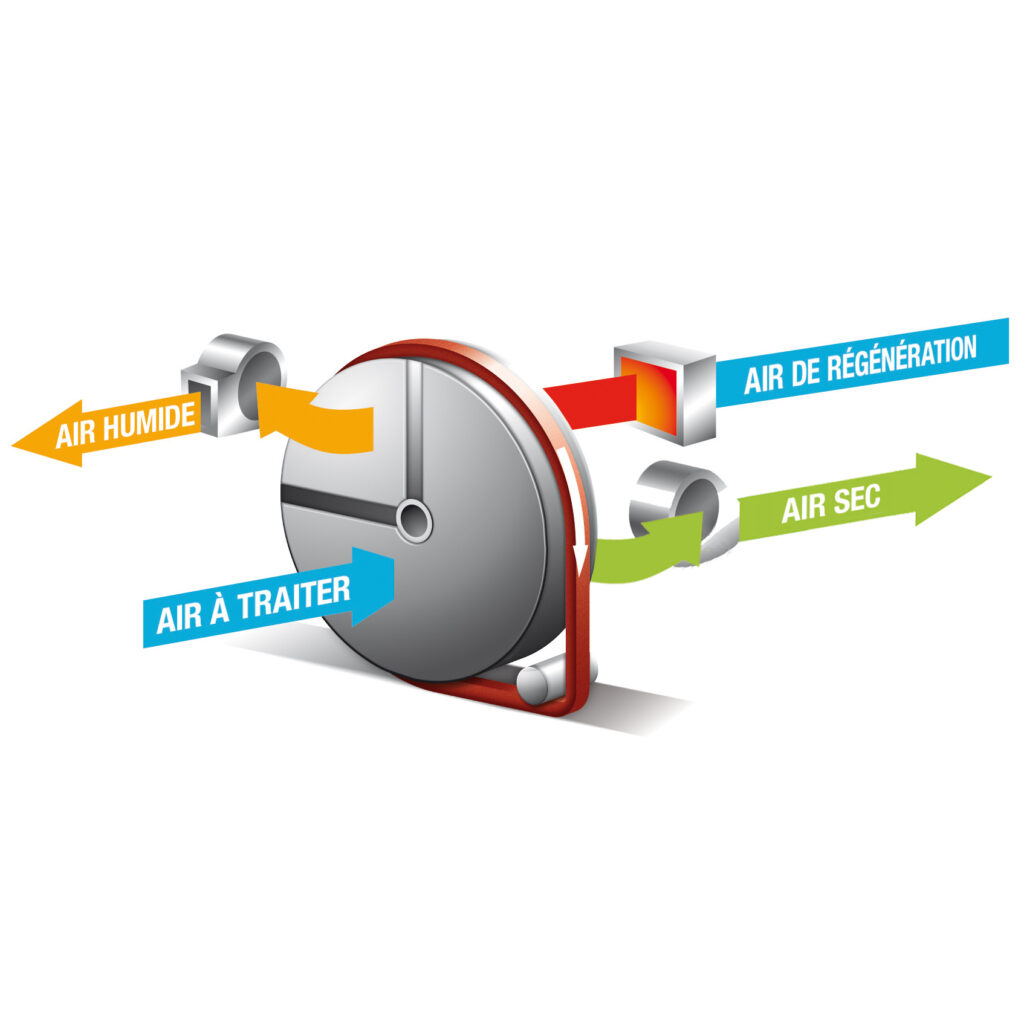

To effectively control humidity in the air and combat corrosion, DESSICA uses adsorption dehumidification technology with a desiccant wheel. The process is based on two opposing air flows that regenerate the silica gel impregnated wheel, which is a highly absorbent material. Unlike chemical corrosion inhibitors, this method is environmentally friendly. By using an air dehumidifier, it is no longer necessary to apply inhibitors, which simplifies the process and reduces costs while speeding up the drying time.

Les avantages de la solution DESSICA pour lutter contre la corrosion

- Réduire les coûts d’entretien: En contrôlant l’humidité, vous diminuez les besoins en peinture antirouille et en réparations fréquentes.

- Diminuer la fréquence des opérations de maintenance et de réparation : Avec une atmosphère sèche, les fréquences de maintenance des équipements sont réduites, prolongeant ainsi leur durée de vie.

- Respect de l’environnement: Contrairement aux traitements chimiques appliqués sur les métaux, la déshumidification par air sec ne produit aucun résidu polluant, ce qui la rend respectueuse de l’environnement.

- Pérennité de la solution: vous assurez la longévité de vos équipements et bâtis et optimisez leur performance dans le temps.

Services de location et installations temporaires DESSICA pour tester la solution

DESSICA propose une offre de location flexible de services et solutions temporaires. Vous pouvez tester les équipements sur une courte période allant de quelques semaines à plusieurs mois pour évaluer leur efficacité avant d’investir dans une solution à long terme.

Pour toutes les industries exposées à des environnements humides, la déshumidification est la solution clé pour lutter contre la corrosion.

LES APPLICATIONS

La plupart des industries agroalimentaires sont concernées par la maîtrise de l’hygrométrie des ateliers.