Preventing condensation in industrial buildings

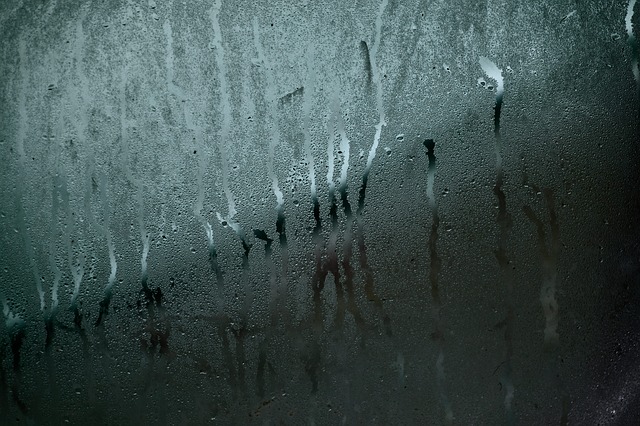

Condensation in industrial premises and warehouses is a common problem that can affect both production processes and employee safety. Humid air in a closed environment leads to the appearance of condensation on walls, ceilings and equipment. If left unchecked, this can cause long-term damage, including corrosion of metal structures and machinery.

What is condensation and why prevent it?

Condensation occurs when humid air comes into contact with a colder surface, leading to the formation of water droplets. This residual moisture can cause corrosion, especially in industrial environments where metal equipment is everywhere. It is therefore essential to prevent this moisture build-up in order to protect machines, buildings, and the workers safety.

In addition to material issues, condensation can also create a conducive environment for the growth of mould and fungi, particularly in the food industry where hygiene is crucial. A proactive solution to combat this phenomenon is to regulate the air humidity using appropriate dehumidification systems.

Solutions to prevent condensation

1. Keep the room airtight

One of the first steps in preventing condensation is to ensure that the room is well sealed to limit the entry of moist outside air. This enables not only to reduce the risk of condensation but also to maintain a constant temperature and humidity inside.

2. Control relative humidity

Condensation becomes a problem when the relative humidity in the air exceeds a certain threshold. By using industrial dehumidifiers, such as those offered by DESSICA, you can maintain a controlled level of humidity. This level is ideally below the critical threshold, thus preventing the formation of condensation on cold surfaces.

DESSICA’s industrial dehumidifiers use desiccant technology, which is a silica gel drying wheel that captures moisture from the ambient air. This system is particularly effective in environments where temperatures are low, such as cool stores, water treatment plants, hydraulic and nuclear power stations.

Industrial applications

Avoiding condensation is critical in various industrial sectors.

Agri-food industry

In food packaging and wrapping plants, condensation can lead to product deterioration and compromise hygiene standards. Maintaining a dry, sterile environment is essential to extend the shelf life of food and reduce airborne contamination.

Energy

Dehumidification systems protect critical equipment (boilers, turbines, generators) from condensation and corrosion in nuclear power plants and hydraulic stations. It also ensures drying during shutdown periods. In addition, these systems ensure optimal restart of alternators, thereby reducing moisture-related risks and improving the safety and efficiency of installations.

Water Treatment

In pumping stations and drinking water treatment plants, condensation and sometimes even mould quickly damage equipment and protective coatings. In summer and mid-season, cold surfaces such as pipes become covered in condensation due to the temperature difference between the water and the surrounding air. In winter, the evaporation from open filters creates high humidity, making the walls damp. Traditional ventilation systems are insufficient and increase energy costs during winter.

Plastics processing and moulding

To speed up press production, it is often necessary to cool plastic moulds with an ice water circuit. However, in summer, the high humidity in the workshop can cause condensation on the moulds. This affects product quality and requires the mould temperature to be adjusted, which limits the cycle time reduction.

The advantages of DESSICA solutions

There are several advantages to using DESSICA industrial dehumidifiers:

- Reduced maintenance costs

- Extended equipment service life

To maintain a healthy industrial environment and avoid the formation of condensation, it is essential to invest in effective dehumidification solutions. Whether you manage a water treatment plant, a nuclear power station or an agri-food production site, DESSICA offers systems tailored to each specific need. Our technical sales engineers are available to check your installations and offer you customised solutions to ensure optimum humidity control in your premises. Contact us today for a personalised analysis.